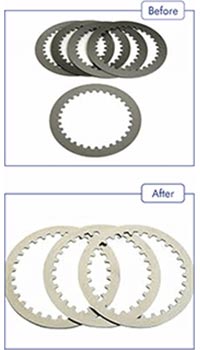

- Component Name : Clutch plate

- Present method : Aqueous cleaning

- Production rate : 40000 per shift (12 hour/ shift)

- Problem faced : Slow process, Short bath life and higher operating cost.

- Input contamination level : 10 mg

- Expected output cleanliness : 1 – 2 mg

Solution provided by GALA :

Single chamber solvent based vacuum cleaning.- Pero machine

Cleaning Cycle –

- First Stage : Filling and flooding

- Second Stage : Ultrasonic and splash flooding

- Third Stage : Vapour degreasing

- Fourth Stage : Vaccum Drying